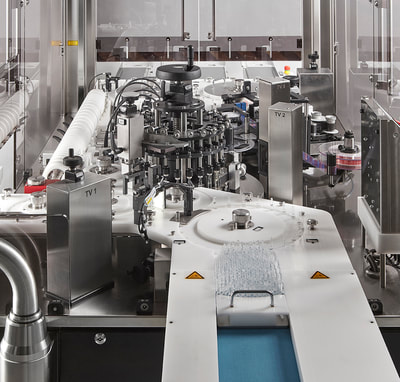

RS1-LAB inspection, leak test and labelling machine for injectable products

Automatic inspection and leak test machine, RS1-LAB was designed to combine CMP's know- how and experience in camera visual inspection with HVLD (High Voltage Leak Detection) system.

Furthermore this model is equipped with an integrated labelling unit for the products which passed all the previous inspections

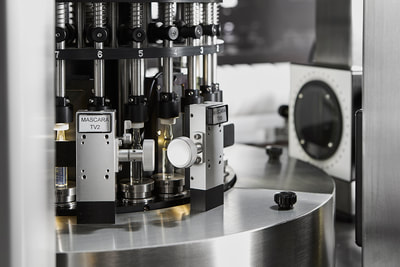

The machine is equipped with 4 leak test stations and a rotation system in order to improve the quality of the control (360° total surface inspection).

To reach a production output of 24.000 pcs/h. is also available the model RS2-LAB, composed of 2 modules integrated in just one frame.

Furthermore this model is equipped with an integrated labelling unit for the products which passed all the previous inspections

The machine is equipped with 4 leak test stations and a rotation system in order to improve the quality of the control (360° total surface inspection).

To reach a production output of 24.000 pcs/h. is also available the model RS2-LAB, composed of 2 modules integrated in just one frame.

|

Production output: up to 200 pcs/min

Range of diameters: from 8 to 32 mm

Max. height: 110 mm

Power consumption: 3,7 KW

Power supply: 230 V single phase, 50-60 Hz

Compressed air: 6 bar

Air consumption: 200 L/min

Weight: 1600 Kg

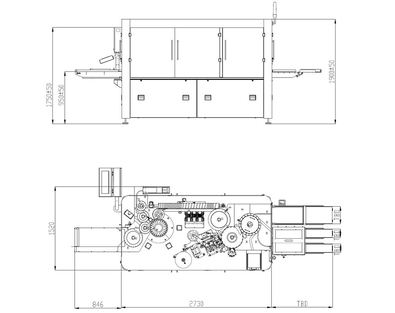

Dimensions: 4380 x 1470 x 1900 h mm

Design: Complies with current GMP regulations. Software in compliance with 21 CFR part11

|

DOWNLOAD

| |||||||

|

APPLICATION

• Ampoules, vials and cartridges • Capacity: from 1 ml to 30 ml • Liquid or freeze-dried products (cosmetic control) STANDARD INSPECTIONS • Extraneous reflecting and no reflecting particles, fibres, glasses • Correct filling level • Leak test by High Voltage system (HVLD) • Label inspection OPTIONAL INSPECTIONS • Cosmetic control (shape, height, black spots, position of the cap) • Ring/cap colour control • Colour of the product • Printing • Glass defects • Plunger inspection (for cartridges) |