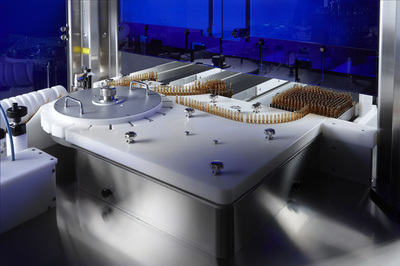

RS1 inspection and leak test machine for injectable products

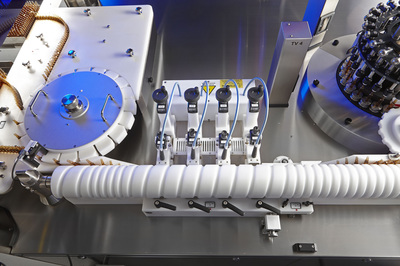

Automatic inspection machine RS1 has been projected to integrate CMP's know-how and experience in camera based visual inspection and HVLD (High Voltage Leak Detection) system. The machine is equipped with 4 leak test stations and a rotation system in order to improve the quality of the inspection.

RS1 can handle ampoules, vials and cartridges with a capacity from 1 ml to 30 ml. A combination of back and bottom lights and CMP software allow to customize the machine as necessary.

To reach a production output of 24.000 pcs/h. is also available the model RS2, composed of 2 modules integrated in just one frame.

RS1 can handle ampoules, vials and cartridges with a capacity from 1 ml to 30 ml. A combination of back and bottom lights and CMP software allow to customize the machine as necessary.

To reach a production output of 24.000 pcs/h. is also available the model RS2, composed of 2 modules integrated in just one frame.

|

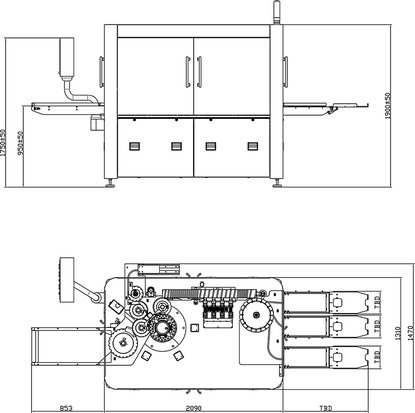

Production output: up to 200 pcs/min

Range of diameters: from 8 to 32 mm

Max. height: 120 mm

Power consumption: 3,7 KW

Power supply: 230 V single phase, 50-60 Hz

Compressed air: 6 bar

Air consumption: 200 L/min

Weight: 1600 Kg

Dimensions: 2940 x 1470 x 1800 h mm

Design: Complies with current GMP regulations. Software in compliance with 21 CFR part11

|

DOWNLOAD

| |||||||

|

APPLICATION

• Ampoules, vials and cartridges • Capacity: from 1 ml to 30 ml • Liquid or freeze-dried products (cosmetic control) STANDARD INSPECTIONS • Extraneous reflecting and no reflecting particles, fibres, glasses • Correct filling level • Leak test by High Voltage system (HVLD) OPTIONAL INSPECTIONS • Cosmetic control (shape, height, black spots, position of the cap) • Ring/cap colour control • Colour of the product • Printing • Glass defects • Plunger inspection (for cartridges) |