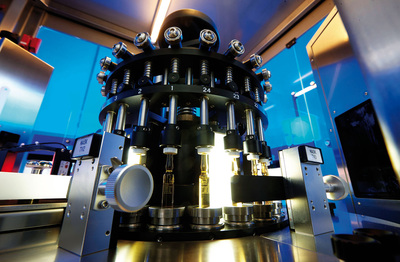

SA12 inspection machine for ampoules, vials or cartridges

Automatic inspection machine SA12 has been projected as an answer to our Customers’ needs and advices.

The productivity up to 200 pcs/min, the compact design and the performances have been setting SA12 as the leading unit of our production offer.

SA12 can handle ampoules, vials and cartridges with a capacity from 1 ml to 30 ml. A combination of back and bottom lights and

CMP software allow to customize the machine as necessary.

Possible integration with leak test unit to check containers' integrity.

The productivity up to 200 pcs/min, the compact design and the performances have been setting SA12 as the leading unit of our production offer.

SA12 can handle ampoules, vials and cartridges with a capacity from 1 ml to 30 ml. A combination of back and bottom lights and

CMP software allow to customize the machine as necessary.

Possible integration with leak test unit to check containers' integrity.

|

Production output: up to 200 pcs/min

Range of diameters: from 8 to 32 mm

Max. height: 120 mm

Power consumption: 3 KW

Power supply: 230 V single phase, 50-60 Hz

Compressed air: 6 bar

Air consumption: 200 L/min

Weight: 1400 Kg

Dimensions: 3250 x 2160 x 1850 h mm

Design: Complies with current GMP regulations. Software in compliance with 21 CFR part11

|

DOWNLOAD

| |||||||

|

APPLICATION

• Ampoules, vials and cartridges • Capacity: from 1 ml to 30 ml • Liquid or freeze-dried products (cosmetic control) STANDARD INSPECTIONS • Extraneous reflecting and no reflecting particles, fibres, glasses • Correct filling level OPTIONAL INSPECTIONS • Cosmetic control (shape, height, black spots, position of the cap) • Ring/cap colour control • Colour of the product • Printing • Glass defects • Plunger inspection (for cartridges) • Leak test |