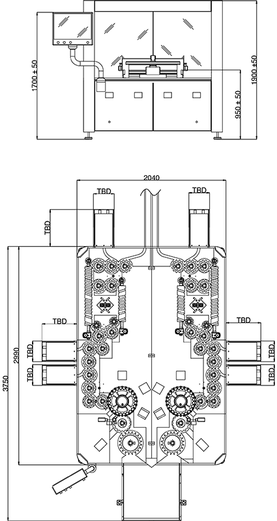

SA18-L inspection machine for lyo products

Automatic inspection machine SA18-L is the specific model for visual inspection of lyo products in glass container up to diameter 46 mm.

Equipped with cameras for tip/cap control, particles on the external surfaces and glass defects, in SA18-L can be integrated the headspace control for integrity testing (performed by TDLAS method).

Equipped with cameras for tip/cap control, particles on the external surfaces and glass defects, in SA18-L can be integrated the headspace control for integrity testing (performed by TDLAS method).

|

Production output: 300 pcs/min

Range of diameters: from 8 to 46 mm

Max. height: 120 mm

Power consumption: 6 KW

Power supply: 400 V single phase, 50-60 Hz

Compressed air: 6 bar

Air consumption: 400 L/min

Weight: 2100 Kg

Dimensions: 3750 x 2040 x 1800 h mm

Design: Complies with current GMP regulations. Software in compliance with 21 CFR part11

|

DOWNLOAD

| |||||||

|

APPLICATION

• Freeze-dried product in glass containers • Capacity: from 8 mm to 46 mm STANDARD INSPECTIONS • Particles on the cake (upper part, bottom part and sides) • Height of the cake • Glass defects (bottom part and sidewalls) OPTIONAL INSPECTIONS • Cosmetic control (tip/cap control, crimping control, height, stopper, black spots) • Ring/cap colour control • Colour of the product • Printing • Integrity control by oxygen headspace control (TDLAS technlogy) • Semiautomatic stations by cameras' system |